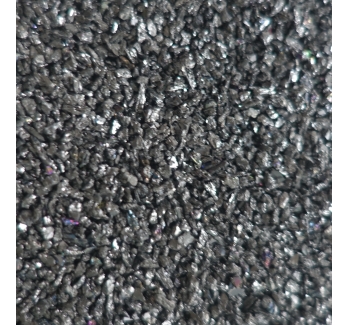

Black Silicon Carbide

Black silicon carbide is produced with petroleum coke, quartz sand and additives .

The powders are the perfect material that specifically manufactured to be used for general abrasive applications in bonded abrasive tools, lapping and polishing processes. It is widely used for grinding non-ferrous materials, finishing tough and hard materials, filling up ceramic parts when the processing cost is important.

Application | Grade | Grit Size | SIC

mass % - min. | Fe(Iron)

mass % - max | C(Carbon)

mass % -max | Magnetic admixture

mass %- max |

Abrasive | AG | F12-F20 | 98.0 | 0.25 | 0.25 | 0.13 |

| F24-F90 | 98.0 | 0.25 | 0.25 | 0.15 |

F100-F120 | 98.0 | 0.25 | 0.3 | 0.15 |

F150-F180 | 97.0 | 0.3 | 0.3 | 0.15 |

F230-F280 | 97.0 | 0.3 | 0.3 | 0.15 |

F320-F600 | 96.0 | 0.4 | 0.4 | 0.15 |

F800-F1000 | 95.0 | 0.5 | 0.5 | 0.15 |

F1200 | 94.0 | 0.5 | 0.5 | 0.15 |

Silicon carbide with 98-99% purity, SIC

Silicon carbide powder and grit FEPA, JIS, GB standard.

Special specification 0-10mm, 200mesh

Powder, micro powder, grains, for sand blasting, grinding, polishing, abrasive making, refractory.

FEPA Standard

F4,F5,F6,F7,F8,F10,F12,F14,F16,F20,F22,F24,F30,F36,F40,F46,F54,F60,F70,F80,F100,F120,F150,F180,F220

F240,F280,F320,F360,F400,F500,F600,F800,F1000,F1200

P grade

JIS standard

#4,#5,#6,#7,#8,#10,#12,#14,#16,#20,#22,#24,#30,#36,#40,#46,#54,#60,#70,#80,#100,#120,#150,#180,#220

#240,#280,#320,#360,#400,#500,#600,#800,#1000,#2000,#3000,#4000,#6000,#8000

20kg or 25kg bags on pallet